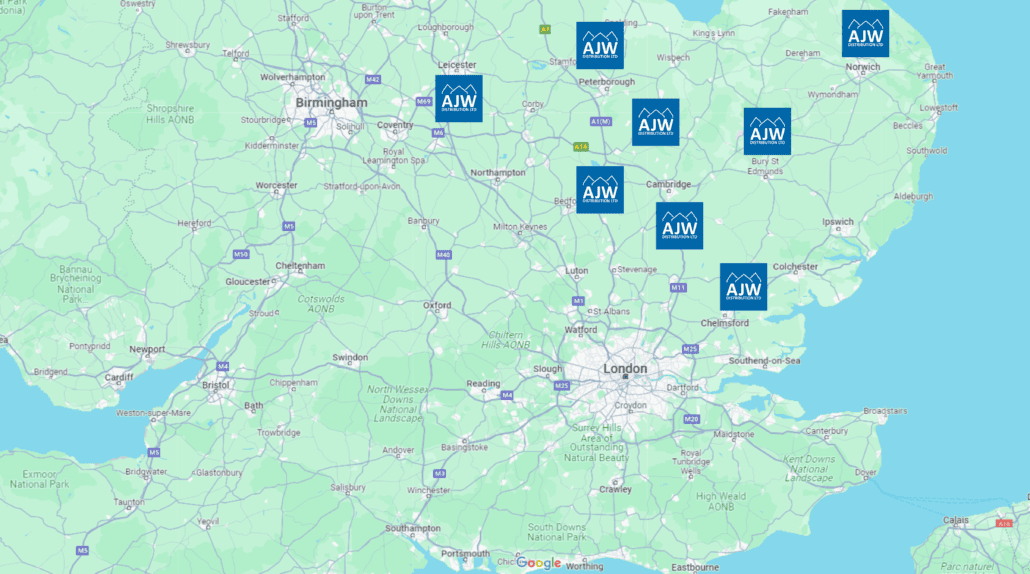

Filon Products Ltd are one of the market leading specialist manufacturers of GRP rooflights and roof sheets.

In today’s market, there are a variety of rooflights and rooflight systems, each offering a wide range of characteristics to suit different pitched, flat and industrial roof applications.

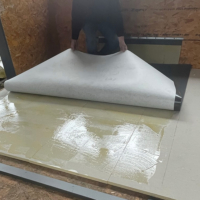

GRP is the most popular rooflight of choice for warehouses and industrial buildings due to its versatility, durability and excellent light diffusing properties, which minimizes glare and distracting shadows. Filon GRP rooflights and sheets are available as natural translucent or opaque in virtually any metal or fibre cement profile, with the Monarch-F range are designed for barrel vault roof systems. Filon GRP rooflights also incorporate UV absorbing surface protection which can eliminate long term discolouring.

In the UK, installers of GRP rooflights are required to meet the UK Building Regulations compliance requirements, the four key areas of the UK Building Regs around GRP rooflights are:

Non-Fragility

When selecting rooflights, contractors must carefully consider reducing or eliminating the potential risk of known or predictable hazards that may occur during or post construction. The HSE’s ‘Health and Safety in Roof Work’ (HSG331) highlights that ‘Roofers account for 24% of all workers who are killed in falls from heights at work. Falls through fragile materials such as rooflights, account for more of these deaths than any other single cause.

Filon GRP rooflights and sheets are available in a wide range of sheet weights, which each provide differing strength characteristics and increased rigidity as the weights increase in thickness. Heavier sheets of a given profile perform significantly better and, in these cases, the increased rigidity is a positive advantage.

When specifying the correct rooflights, designers and contractors should consider rooflights with an expected period of non-fragility that matches that of the roof, considering the likely deterioration of rooflights over time due to UV exposure, environmental pollution, and the internal and external building environment.

For guidance on the correct GRP rooflight sheet weights required for your project, please contact Filon/AJW for further guidance.

Daylighting

Workplace (Health Safety and Welfare) Regulations 1992 states – “Every workplace shall have suitable and sufficient lighting which shall, so far as is reasonably practicable, be by natural light”. These comments are also restated in HSG38 – Lighting at Work.

Roof lighting is the most effective method of providing consistent, even daylight in a large building. Rooflights provide up to three times more effective light into a building when compared to windows in a similar area. Diffusing GRP materials are typically used to provide even light distribution and avoid glare.

Thermal performance

‘Thermal Performance’ generally relates to the efficiency with which something retains or prevents the passage of heat. Research has shown that rooflights make a positive contribution to the compliance of Part L of the building regs.

Filon GRP ‘site assembled’ or ‘FAIR (Factory Assembled Insulated Rooflights)’ systems are available with an insulating core to achieve a range of U-values to meet the buildings requirements.

Fire

In the UK, Building Regulations Approved Document B (2019 Issue) sets out the rules for fire safety of buildings. Section B2 covers internal fire spread, and applies to the linings of both the roof and walls of buildings. In general, these are surface spread of flame requirements to BS476 Part 7 (typically Class 1 and Class 3) or to BS EN 13501 Part 5 Section B4 covers external fire spread and applies to external coverings of roof and walls; in general these are fire resistance requirements to BS476 Part 3 (typically AA and AB) or to BS EN 13501 Part 5 BRoof(t4)).

For the majority of industrial buildings, the requirements can be summarised as follows.

- The lining of a roof should normally be rated Class 1 to BS476 Part 7 or Class C-s3,d2 to BS EN 13501 Part 1

- The lining of a wall should normally be rated as follows:

18m and over high & 1000mm or more from relevant boundary: Class 1 to BS 476 Part 7 & Class 0 to BS 476 Part 6

18m and over high & less than 1000mm from relevant boundary: Class 1 to BS 476 Part 7 & Class 0 to BS 476 Part 6

Up to 18m high & 1000mm or more from relevant boundary: Class 3 to BS 476 Part 7

Up to 18m high & less than 1000mm from relevant boundary: Class 1 to BS 476 Part 7

- A concession allows the lining to be rated Class 3 to BS476 Part 7, Class D-s3-d2 to BS EN 13501 Part 1 if the area of the rooflight is less than 5m2, and there is a clear space of 1.8 metres in all directions between each rooflight and should be evenly distributed and not exceed 20% of the floor area of the room

- A single skin sheet must meet the requirements for both the inner ceiling and outer roof surfaces