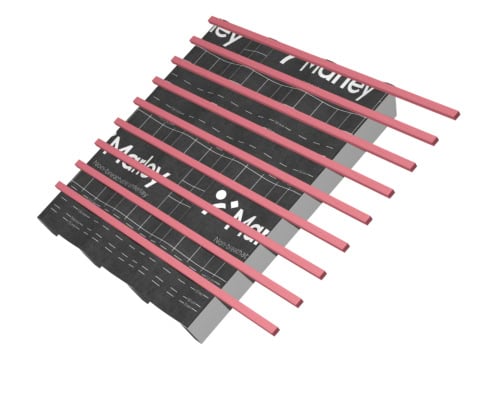

With ongoing debate about the differences between roofing battens, Stuart Nicholson, director for roof systems at Marley, says BBA certification provides further assurance that customers can rely on JB Red for quality and consistency.

Since BS 5534: 2014 was introduced, it has made the process of choosing and grading timber roofing battens much simpler and safer, improving quality and effectively getting rid of the risky practice of grading by eye on site. Now only battens that have been pre or factory graded to BS 5534 are actually allowed to be called roofing battens.

However, more recently, there has been growing debate in the building and roofing trade media about the fact there are still quality differences between battens. Indeed, just because all battens have to comply with BS 5534 requirements, it doesn’t mean that they are all exactly the same. In fact, it is surprising how many differences there can be between similar looking roofing battens – from the way they are graded, through to the type of timber they are made from, the preservative they are treated with and the length of the guarantee.

This means that, as well as BS 5534 compliance, it is increasingly important to be able to provide third party assurance of batten quality to customers in the roofing and building trades, for example BBA certification.

To achieve certification, the BBA carried out a six-month audit at our JB Red manufacturing facility in Gainsborough, where inspectors assessed all aspects of the quality control and manufacturing processes involved with producing the battens. Our latest BBA Agrément certificate gives independent endorsement that JB Red roofing battens meet its strict quality criteria and that they comply with all the requirements of BS 5534.

It is important for all of our customers to know that BBA isn’t just a one-off certification. They continually audit the manufacturing process to make sure it stays consistent and meets the high quality standards that have been set. As part of the audit, the BBA checks our manufacturing line from beginning to end – from the raw material coming in, to its treatment and grading, through to the finished product ready to deliver. This includes looking at our testing procedures, quality checks, equipment calibration and materials traceability.

The BBA accreditation is stamped on every batten, reassuring specifiers, architects, contractors and merchants that they can rely on red to not only be BS 5534 compliant, but also provide them with extremely high manufacturing standards.