A New Head Office and Fabrication Workshop

Our QuadCore Roof Panels and QuadCore AWP Wall Panels have been used to create new head offices for Lester Cladding.

The family-owned business Lester Fabrications has plenty of experience in providing realistic and high-quality roofing, cladding and building envelope solutions, and now they have employed that skill for their own office project.

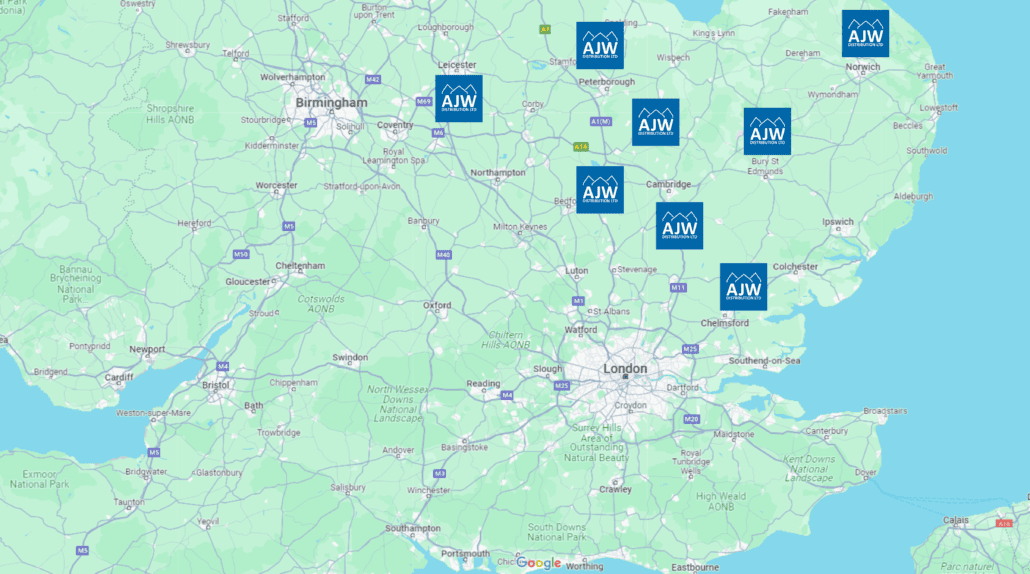

Trading since 1984, the Lester Cladding strand of the company is based in Buckley, Flintshire, and needed a new facility to meet the demands of their growing business, whilst also staying close to their roots in Flint. Their self-funded, self-managed and self-built approach – as well as self-designed by their in-house design team – highlights the range of their expertise and quality assurance.

The building itself consisted of a workshop and storage area attached to a 3-storey office block, spanning roughly 1600 m2. The project afforded a 21.5% increase in floor area for the business, supporting future expansion and providing significant flexibility due to its portal frame structure and open floor area. Our QuadCore KS1000RW Roof Panels and QuadCore AWP Wall Panels were supplied across the warehouse, the latter in a horizontal application.

Dan Robinson, of Crusoe Architects, said, ‘the building form, cladding design and colour palate were all chosen to create a contemporary building which complements its setting within the landscape.’ Everything about the design promoted cohesion within the structure. The cladding colours harmonise with the corium brick slips, which themselves reference traditional Welsh Slate, and the colour scheme was integrated throughout the building’s interiors, including the internal finishes such as the carpet and tiling.

SECTOR: Commercial & Offices, Industrial

LOCATION: Buckley, Flintshire, Wales

Architect: Crusoe Architects

A bespoke building created to keep up with the company’s growth and demand, Lester Cladding’s head office showcases the breadth and variety of facades that Lester Cladding can undertake.

including the internal finishes such as the carpet and tiling.

The Project

Corium brick slips and shingles were installed onto our Karrier panels around the office area, delivering the same high-performing credentials to this section and supporting a sleek finish to the combined structure. Lester Cladding was the main contractor and sub-contractor for their project, undertaking most of the construction without assistance – including the groundwork, fit-out, and cladding. Crusoe Architects worked with Lester Cladding’s in-house design office to develop the building envelope design, whilst NR Groundworks Ltd aided with the groundworks and Kendley Steel for the steel frame.

The speed of build that our QuadCore KS1000RW Roof Panels and QuadCore AWP Wall Panels provided, along with Lester Cladding’s extensive experience, enabled them to move into their new offices in October 2021. The building envelope was constructed through the winter months of 2020/2021, and the quick installation time and the robust airtightness of the prefabricated roof panel systems meant there was an improved weather resilience throughout a period of heavy rainfall and cold temperatures, compared to conventional built-up systems. Whilst also reducing construction risks and significantly improving onsite safety, having a single supplier for the wall and roof products streamlined deliveries and people onsite, ensuring a seamless installation.

Performance

For a big warehouse such as this, large amounts of heat can be lost through poor insulation. Our QuadCore insulated core panels featured in both products provides high levels of thermal efficiency and fire performance. QuadCore is considerably more efficient than mineral fibre, enabling thinner and lighter walls. The factory-engineered jointing also reduces thermal bridges and provides high levels of airtightness, helping to keep operating costs of heating the facility as low as possible. The reduced thickness due to the thermal efficiency of QuadCore, together with the ease and speed of installation attracted Lester Cladding to these products.

The products are also easy to disassemble, ensuring the potential to be reused or recycled at end-of-life process, reducing wastage. Both types of panel are produced at our UK facilities, which operate at net-zero energy on an aggregate basis throughout the year, and achieve zero waste to landfill. QuadCore’s energy efficiency helps to reduces the operational carbon of the new facility, and its reliable performance provides a long-lasting solution to reducing carbon emissions.