How to stay safe when installing an insulated panel roof

Health and safety may be a common source of annoyance in some industries, but for construction, it is a vital part of life on site. The building trade is undoubtedly one of the most physically demanding and dangerous sectors to work in. This is because much of the manual labour in the industry is unavoidable. Falls from height present the greatest risk to life, accounting for almost half of all fatal injuries in the last five years. However, in many cases, accidents of this nature can be minimised with careful planning, collaboration and implementing simple safety measures. The same practices apple apply when installing an insulated panel roof.

Who is responsible for reducing risk?

Before looking at the products and systems available to improve onsite safety, it is important to establish who plays what role when it comes to ensuring good health and safety practice. Under the Construction (Design and Management) Regulations 2015 (CDM), building designers must “eliminate, reduce or control foreseeable risk” that may arise during the construction, maintenance and use of the completed building when preparing or modifying their plans. This includes the handling and installation of roofing materials. Meanwhile, the ‘client’ (the one commissioning the new or refurbished roof) is ultimately responsible for site safety. As a result, they are expected to provide adequate time and resources to ensure all work can be carried out safely and to a high standard. These are the main people responsible for putting the right safeguards in place and reducing risk.

However, it is the individuals who are carrying out the work who must take responsibility for their own safety and that of their workmates. This is achieved by observing any measures that have been put in place, doing training related to specific systems when it is available, and educating themselves on the dangers involved in working at height.

How can insulated panels help to improve height safety?

Metal-faced insulated panels have been used in roofing applications for decades due to their excellent levels of thermal, structural and fire performance. Combining internal and external metal facings, insulation and waterproofing in a single rigid panel, these products can be used to create a wide range of roof types, from typical flat or pitched roofs to dynamic curved designs. As there is no need for multiple layers to be assembled, the panels provide a safe, walkable platform as soon as they are fixed to the supporting steelwork. They are also quick to install, reducing the amount of time spent working at height.

Another thing that can speed the job up is the size of panels available, reducing the time installers need to spend on the roof. Up to 2 metres wide and 20 metres long, large areas can be covered in a relatively short space of time. Mechanical handling equipment is essential for these larger panels and has also become the standard for most insulated panel system installations, with roof panels typically being craned into place. In turn, this reduces the risk of injury from manual handling and further speeds up the work. However, it is essential that installers are properly trained in the use of such equipment, and competent to safely lift and secure the panels in place.

How do I ensure height safety throughout a building’s lifetime?

No matter how robust the roof itself may be to walk on, the risk of a slip, trip or fall, is ever-present. This can occur both during construction and during any maintenance that may need to be carried out over the life of the building.

One of the best ways of protecting workers on roofs is to install and operate fall arrest systems, from simple passive barriers installed around the perimeter of a flat roof, to rail-based anchor systems designed to provide personal protection across the whole roof area. These are typically fixed to the top skin of the panel, which minimises the dynamic load on the roof in the event of a fall and avoids penetrating the insulation layer and causing a thermal bridge. They are easy to integrate with insulated panel systems and should be regarded as an essential part of any new roofing system. They can also generally be retrofitted to existing roofs.

It is essential that such equipment is properly installed, suitable for the application and tested to the appropriate third-party standards. Whilst this is the responsibility of the specifier, building owner, and installer of the safety equipment, at the end of the day it is only effective if it is used correctly by the people working on the roof.

Don’t take the risk

No matter what role you play onsite, it is important that health and safety are adhered to by everyone. The good news is it is possible to reduce the risk to workers without compromising on final build quality or project efficiency. This is achieved by using roofing systems that not only achieve the high levels of performance you want for your roof project but that also offer integral safety benefits during installation. Construction, by its nature, is always going to be an industry that faces high levels of safety risk. However, through adequate planning, clear communication between project parties and investment in the right safety equipment, we can ensure peace of mind throughout a building’s lifetime.

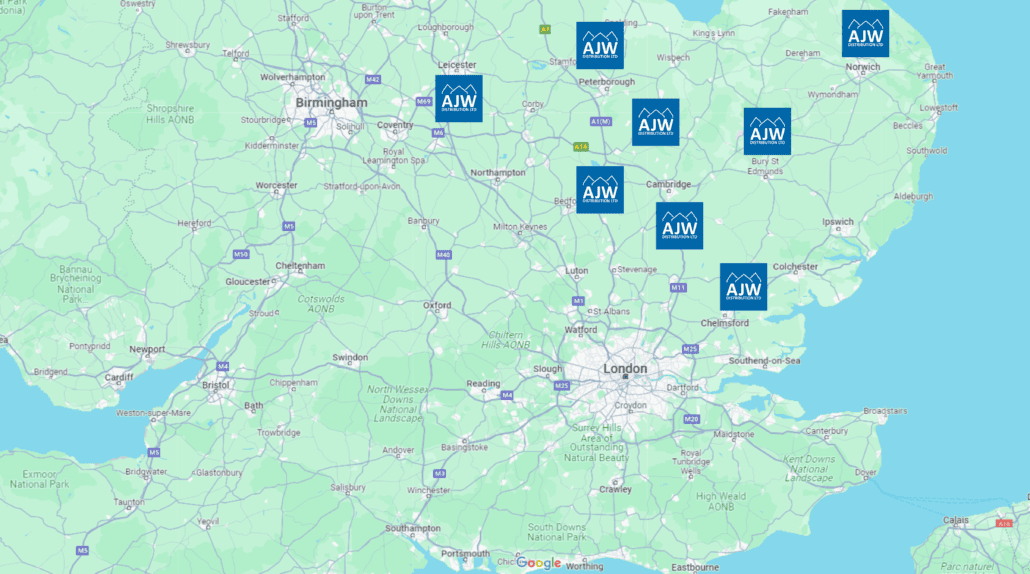

This article was brought to you by Kingspan who are widely recognised in the industry for the high quality and performance of its products, as well as its commitment to excellent customer service and technical support. You can take a look at our range of sheeting panels including insulated panel roof sheets here.