Why are our buildings an important consideration when tackling the climate crisis?

The last 12 months has seen considerable developments in the global response to the climate crisis, from widespread protests to ambitious legislative commitments, such as the UK’s pledge to reduce greenhouse gases by 2050. However, there is still much more work to do to reduce our emissions and keep global temperatures under the required 2˚C, and buildings have a significant part to play in tackling the climate crisis.

Globally, buildings and construction contribute 39% of all carbon emissions, with the majority of this coming from operational emissions from the energy used to heat, cool and light buildings. To reduce this, it is vital that we ensure every building, new or old, uses energy as efficiently as possible through its lifetime.As a result, we are likely to see a significant improvement and take major steps forward to tackling the climate crisis.

How can we build more efficient buildings?

Whether you are refurbishing an existing building or constructing something new, the first step is to ensure a highly insulated building envelope. Commonly known as taking a fabric-first approach, this reduces the amount of energy needed to heat the internal space, delivering energy and cost savings over the long-term with little or no maintenance.

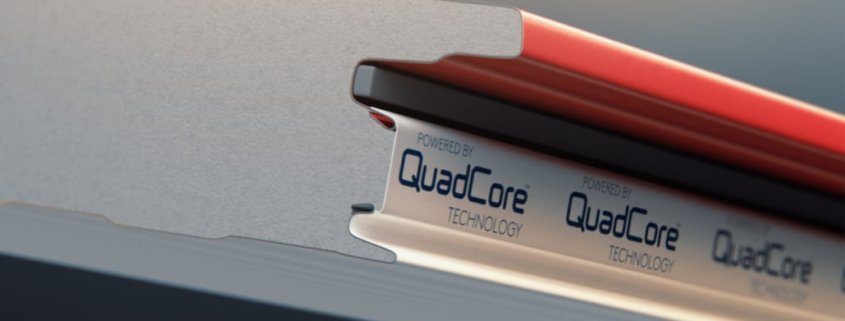

Panelised building systems that use modern closed-cell insulation core technology, like Kingspan QuadCore™, can provide considerable benefits in this area. They can achieve thermal conductivities as low as 0.018 W/mK, resulting in far less thermal transfer than other commonly used materials. For example, man-made mineral fibre has 89% more thermal transfer than QuadCore™, based on the same thickness. This means that a highly efficient building envelope can be created using slimmer panels which are easier and faster to install and can help to maximise internal space.

However, for fabric-first schemes to meet their potential, it is critical that they’re deployed as part of a holistic, quality-controlled package by qualified installers. Poor attention to areas such as the jointing, detailing and ventilation during the installation stage can undercut a building’s final fabric performance and energy waste-reduction. Insulated panels are typically designed to fit together with a factory-engineered jointing system that ensures airtightness and insulation continuity without increasing the complexity of installations.

Daylighting and low energy building services should also be considered as part of this energy reduction process. In addition to cutting energy consumption, many of these measures can help to create more comfortable and healthier spaces for occupiers.

Once the initial demand has been reduced, depending on the project, it then may be possible to offset at least a significant proportion of whatever is remaining through the use of renewable energy generation systems such as rooftop solar photovoltaics (PV). Installing solar PV arrays on unused roof spaces can not only create a more sustainable facility but can also significantly reduce energy bills over the long term, especially if combined with battery technology to harvest and store excess energy.

Do the products we use matter?

However, to create truly sustainable buildings, we need to think beyond just what they can achieve but how they are made. The environmental impact of the manufacture and transportation of building materials is becoming an increasingly important consideration, with consumers turning to contractors for guidance on choosing sustainably produced systems.

This is an area many manufacturers are looking to improve. For example, QuadCore™’s high thermal performance means thinner panels can be manufactured faster, with less energy, and using fewer raw materials, reducing carbon emissions and optimising natural resource use. In the UK, this is done at a facility that uses 100% renewable energy (either generated on-site or procured) and has achieved BES 6001 Responsible Sourcing certification. The reduced thickness of the panels also means that they can be transported to site more economically, saving on transport emissions.

The insulation material itself has Low Global Warming Potential, which is produced using a blow agent which is CFC and HCFC free. It is also third-party verified to EN 15804 Environmental Product Declarations (EPDs) on EcoPlatform and Greenbooklive. The product’s material efficiency is taken further with the inclusion of recycled materials; such as 20%-25% recycled steel. As part of our Planet Passionate pledge, it is exploring ways to incorporate upcycled PET plastic from consumer plastic waste in all QuadCore™ insulation by 2025.

Sustainability as standard

In its latest report to Parliament, the Committee for Climate Change called for “bold and decisive action” from the government to improve the energy efficiency of building to meet its net-zero by 2050 ambitions. This presents significant opportunities for contractors who are ready to think holistically about their buildings. From the fabric to renewable technologies, providing clients with clear advice and guidance on the best approach to take can not only help to create a more sustainable, efficient, and futureproofed built environment but potentially raise the value of a contract.

Ultimately, the choice of product you select is important in supporting tackling the climate crisis. However, as this article has shown the benefits expand further than that.

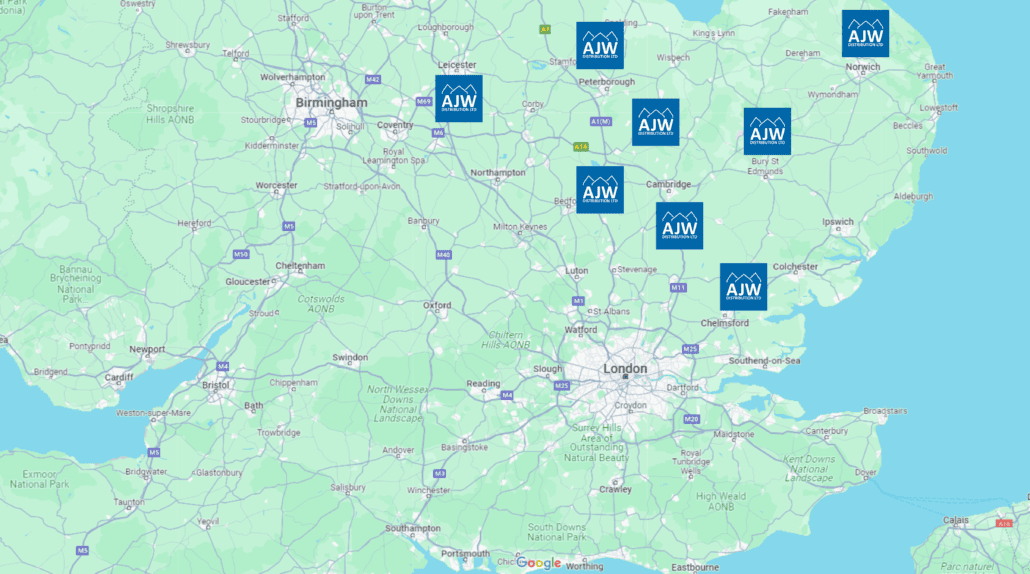

To learn more about Kingspan you can visit their website here. Alternatively, you can view our full range of Kingspan on our website here.